Urban Mining

2 August 2015

Download PDF Version: Jobenomics Urban Mining – August 2015

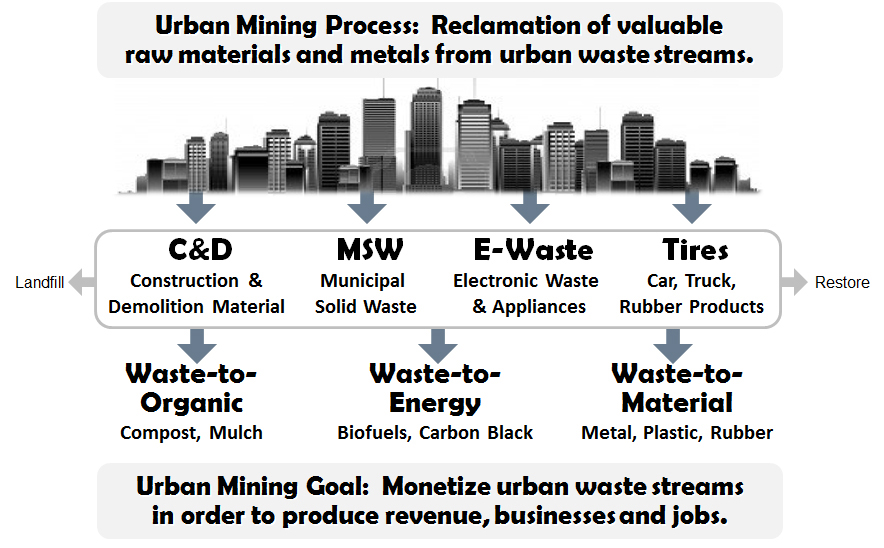

Urban mining is defined as a process of reclaiming raw materials and metals from municipal waste streams including construction and demolition material (C&D), municipal solid waste (MSW), electronic waste (e-waste) and tires. These waste streams contain combustible and non-combustible materials. Combustibles are the carbon-based matter that has a caloric value that can be converted to marketable products via waste-to-organic and energy via waste-to-energy technologies. Non-combustible elements can be reclaimed via waste-to-material technology. Every U.S. community should consider urban mining to (1) reclaim valuable raw materials and metals, (2) reduce landfilling and exporting of toxic waste, (3) mitigate environmental pollution associated with traditional surface and subsurface mining operations, and (4) produce revenue for local business and job creation.

Waste-to-Organic. Waste-to-organic facilities convert biological waste into commercially-viable products such as compost and mulch. Approximately 55% of U.S. landfilled waste is a biodegradable organic waste. When human and animal bio-waste, food scraps, yard trimmings, paper, and wood are landfilled, anaerobic bacteria degrade the organic material, producing greenhouse gases, volatile organic compounds and leachates that are environmentally hazardous.

Approximately two-thirds of U.S. MSW can be composted. Composting is a managed system that uses microbial activity to degrade biological waste so that the end-product is relatively stable, reduced in quantity from the original feedstock, and free from offensive odors. Compost is widely used as a soil amendment to improve soil structure, provide plant nutrients, conserve water, sequester carbon, and facilitate revegetation of disturbed or eroded soil. In the U.S., 28% of all cropland is eroding above soil tolerance rates, resulting in diminished agricultural yields. Composting offers up to four times more business and job creation opportunities than landfilling or incineration. For every million tons of MSW composted, 1,400 jobs can be created. Mulch is closely related to compost and used as a surface covering to retain moisture, contain weeds and make landscaping more attractive.

Waste-to-Energy. Waste-to-energy facilities use incineration, pyrolysis, plasma or gasification to convert organic waste into biofuels that can be used to generate electricity or produce synthetic gas, oil, tars, and other marketable products. Incineration (burning) is the oldest and most common process, but is generally considered the dirtiest. However, modern incinerators are more efficient and cleaner burning. Pyrolysis burns waste material in an oxygen-free environment, producing carbon black (a commodity used in paints and toner cartridges), and synthetic fuels and substances. Pyrolysis is becoming increasingly popular but produces lots of ash and is often expensive. Plasma, which is essentially lightning in a bottle, is the most modern but yet unproven. Due to its ultra-high temperature, plasma is ideally suited for eliminating toxic waste including nuclear waste. Gasification is considered to be the cleanest and most cost-effective waste-to-energy system that mainly produces synthetic gas as an end-product. Gasification is in use in over ten countries. A typical waste-to-energy plant employs several hundred people.

Waste-to-Material. Waste-to-material facilities reclaim non-organic elements and metals from MSW, C&D, e-waste, and tires. Advanced technology material recovery facilities can produce over $30 million worth of annual profits and hundreds of jobs for a medium-sized city. Unfortunately, most city managers do not realize that they forego this source of revenue by landfilling or exporting items that contain high-value materials, such as precious metals, common metals, and plastic and rubber products.

E-waste (consumer electronics and appliances) is the fastest growing waste stream in the U.S. According to the U.S. Environmental Protection Agency (EPA)[1], 2.37 million tons of consumer electronics and computer-related waste is ready for end-of-life management with 5 million tons in storage. The EPA[2] estimates 4.1 million tons of major appliances, 1.8 million tons of small appliances and 21.0 million tons of miscellaneous durable goods are discarded annually. Each year, 16 million household appliances (refrigerators, air conditioners, dehumidifiers) that contain ozone-depleting refrigerants and foam blowing agents are ready for special handling and disposal.

The EPA calculates that 75% of all U.S. consumer electronics and computer-related waste is landfilled and 25% is recycled. Of the 25% recycled, 80% is exported to countries where extraction processes are often unregulated and unsafe. Consumer electronics and computer-related waste grew by 120% in the last decade and is forecast to exceed this growth rate in the next decade largely due to the advent of mobile phones, flat panel displays, and cloud computing. Worldwide, 2 billion PCs are currently in operation will be soon ready for end-of-life management. In the United States, over one billion (6 million tons of which two-thirds are toxic due to lead content) TV and computer monitors with cathode ray tubes are now ready for end-of-life disposal. Americans also dispose of an untold amount of other e-waste related materials such as 8 million vending machines; tens of millions of stoves, dishwashers, HVAC systems, water heaters, ducting, wiring, and light fixtures; and tens of millions of tons of industrial scrap metals and plastics that can be reclaimed by waste-to-material plants. National disasters produce vast stockpiles of non-organic elements and metals.

Americans discard 300 million scrap tires per year. Scrap tire markets include tire-derived fuel, ground rubber, aggregates, and exports. The primary means of disposal of scrap tires is tire-derived fuel due to their high heating value. The typical selling price for tire-derived fuel is approximately $50/ton. Ground rubber mulch, pellets and powders sell for between $300/ton and $8,000/ton for ultra-fine and pure mesh. Pyrolysis of waste tires generates combustible gases, oil, and char products. Approximately 25% of a scrap tire consists of steel that currently sells for $250/ton.

In Conclusion, American urban mining is decades behind Europe and China in terms of advanced technology material recovery systems. Of the 3,000+ U.S. recycling companies, the vast majority use manual processes to strip out high-value metals and discard the remaining materials in landfills. In many cases, ozone-depleting refrigerants and foams are not handled properly. As a result, Jobenomics started eCyclingUSA LLC (www.eCyclingUSA.com and eCyclingUSA Presentation -22 May 15) to help local communities design and implement turnkey advanced technology material recovery facilities (Advanced Technology Materials Recovery Facilities 2 August 2015) that can safely, cleanly and efficiently monetize high-value waste streams in order to create the revenue necessary to mass-produce new small businesses, which in turn, creates thousands of new inner-city jobs (see Jobenomics Minority-Owned Business initiative: Minority-Owned Businesses – 10 Jan 2014). Urban mining also has many indirect benefits including reducing transportation costs, mitigating the effects of landfilling toxic substances, and producing substantial environmental savings over traditional mining methods. According to the EPA, urban mining uses 75% less energy, emits 86% less polluted air and leaches 76% less polluted water into the ground than traditional surface and subsurface mining operations.

[1] EPA, Electronics Waste Management in the United States Through 2009, published May 2011, http://www.epa.gov/osw/conserve/materials/ecycling/docs/summarybaselinereport2011.pdf

[2] EPA, Municipal Solid Waste in the United States, 2009 Facts and Figures, Table 12, Page 67, http://www.epa.gov/osw/nonhaz/municipal/pubs/MSWcharacterization_fnl_060713_2_rpt.pdf